Together we develop efficient solutions for your components, based on your draft, sample or CAD-data. As specialists for materials, our engineers are happy to assist you in choosing the suitable material. The machined tooling is constructed with the help of the newest CAD-software and the forging process is simulated if needed.

Constructing our own tooling allows for better quality control, a very high degree of flexibility and short lead times for new parts, as well as for product modifications.

The upkeep and maintenance of our tooling is all part of our service, as well as the professional storage. This guarantees you identical subsequent or replacement deliveries over the years.

With a total of 7 drop hammers we produce forgings made of alloyed and unalloyed steel, aluminium, copper, titanium and nickel alloy, weighing from 0.1 kg to approx. 150 kg. We have specialised in producing prototypes and small and medium batches up to approx. 5’000 pieces.

Using different presses and hammers we produce near-net-shaped spindles, flanges, discs and rings This process is particularly suitable for small batches and replacement parts.

Different types of heat treatment can be carried out in our facilities:

Quenching media:

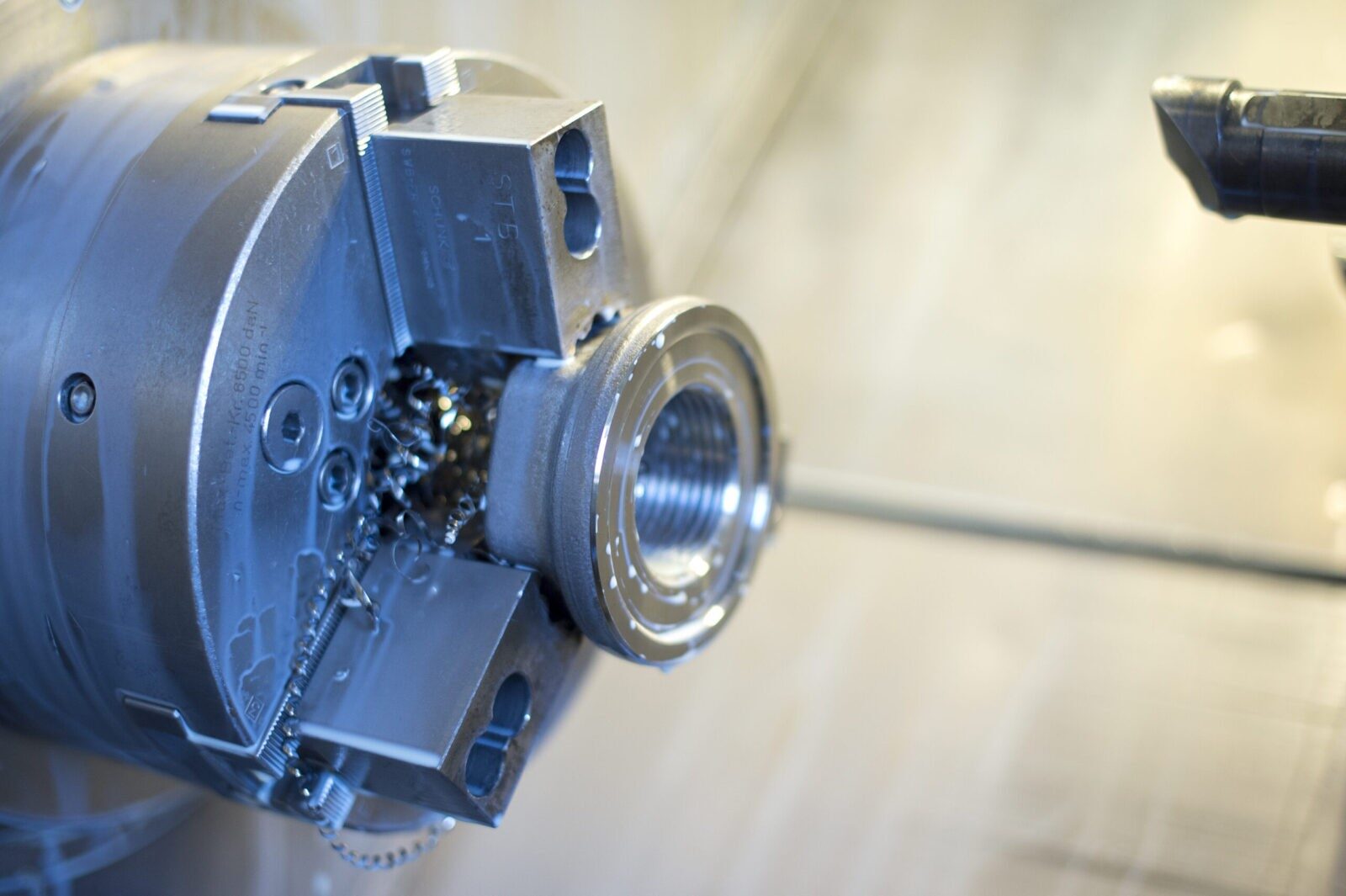

Using multiaxial CNC-controlled lathes and milling machines, we are able to finish our components ready for installation. We are also able to offer contract manufacturing and machining of cast parts.

The forging and machining processes are perfectly coordinated to ensure an efficient service with shorter lead times and lower costs.

A significant benefit of friction welding is the possibility to combine different materials, such as:

Different spray applications are carried out in-house.

Working with our approved network of partners, allows us to offer the following surface finishing procedures:

The sandblasting / peening process cleans the surface and strengthens it once again, leaving you with components that are flawless, clean and free of scale.

We manufacture the individual parts and assembly the mechanical elements for you. We are your partner, from start to finish.

There are different possibilities to mark your parts. This assures complete traceability.

For more than 130 years we’ve been processing metallic materials by massive forming and machining. About 1’500 t of the most common steel grades are available from stock.

Processed materials:

In our metalworking shop we are able to carry out various kinds of metal work. According to customer requests we create a variety of special products, such as: