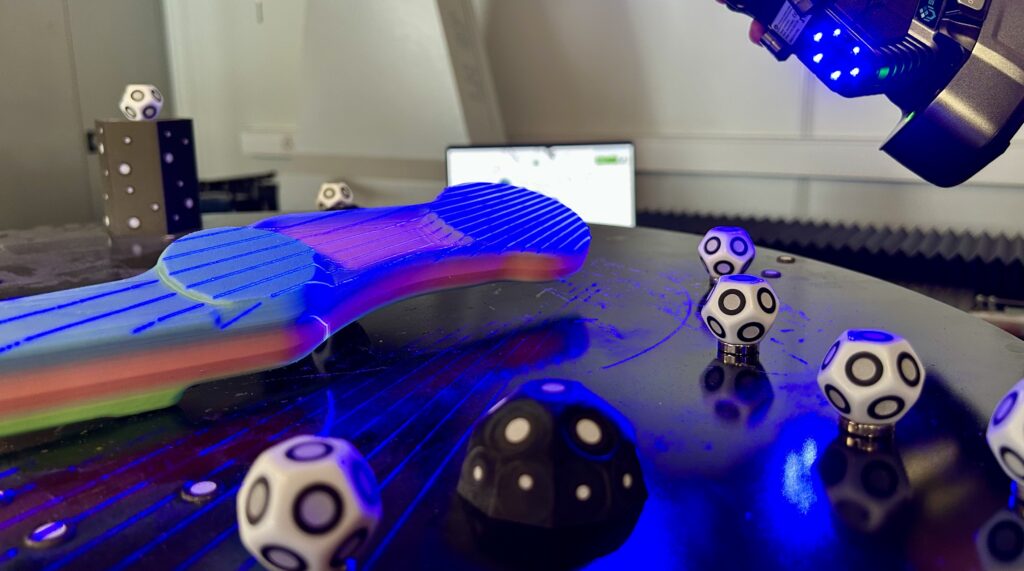

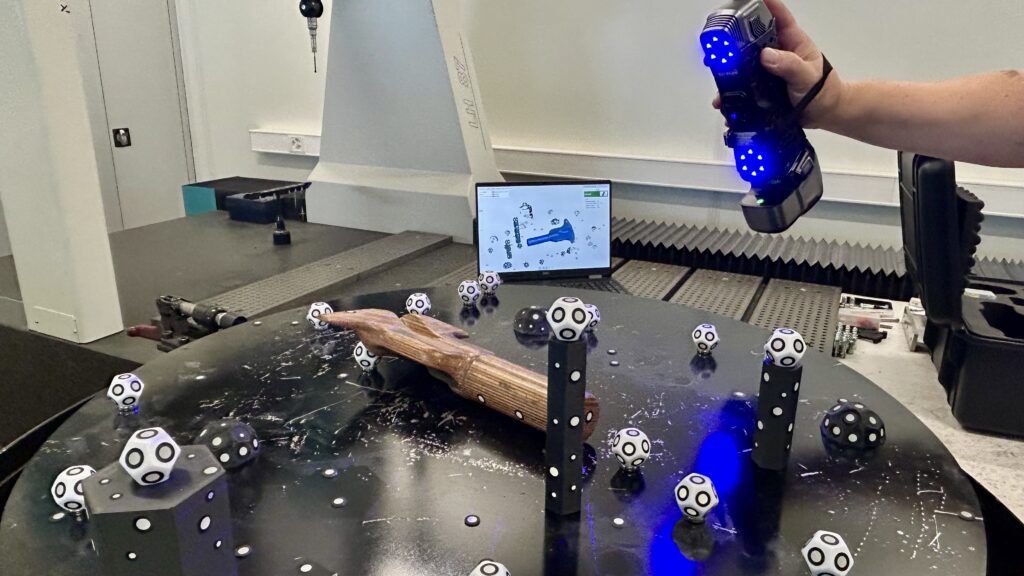

We have further expanded our quality assurance by investing in a new 3D scanner. We are now able to scan sample parts from our customers and create a CAD model using reverse engineering. This means that we can manufacture replacement parts 1:1 based on the sample in-house.

This process also offers huge advantages in terms of quality assurance. Our forging tools can be scanned before use and compared with the CAD file. Any deviations are immediately visible.

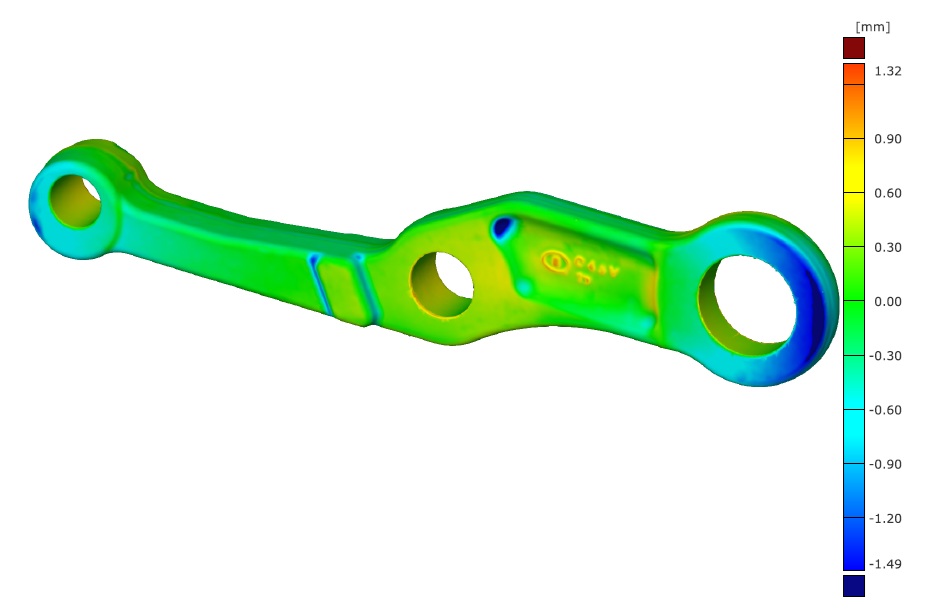

To check our forged or machined parts, we can simply scan them and compare them with the CAD model. Even the smallest geometric differences become apparent.

Our customers have the option of creating a test report.